Panda twin belt spreader

Latest technology in spreading variable materials up to 40m.

Panda twin belt spreader allows the new type of spreading with two belts in great volume capacity hopper. Thanks to the twin belt spreading the volume of hopper has been increased to 20,000 L in highest hopper performance. The standard performing provides 15,000 L hopper capacity. The moving belts are fixed together with the chains to prevent sliding and losing the feeding accuracy.

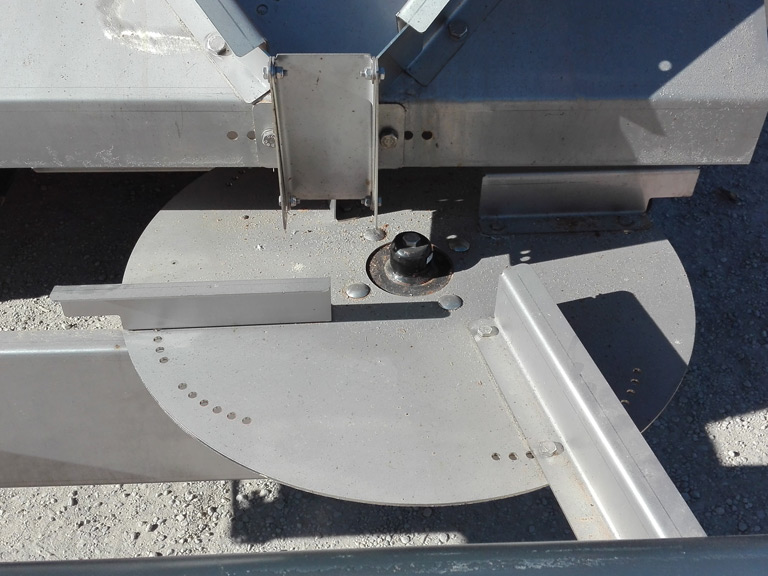

Twin belt spinners are able to be accurate for spreading in long distances for granulate materials up to 40 m and for non granulate 12-16m of spreading. Two spinners are provided in stainless steel for long lasting and durable life span together with two loaders. Spinners are made with 4 paddles which can be adjusted easily for great spreading according to used material.

Features

Hopper screen mash is mounted to the hopper for material screening before it is feeded to the driving spinners.

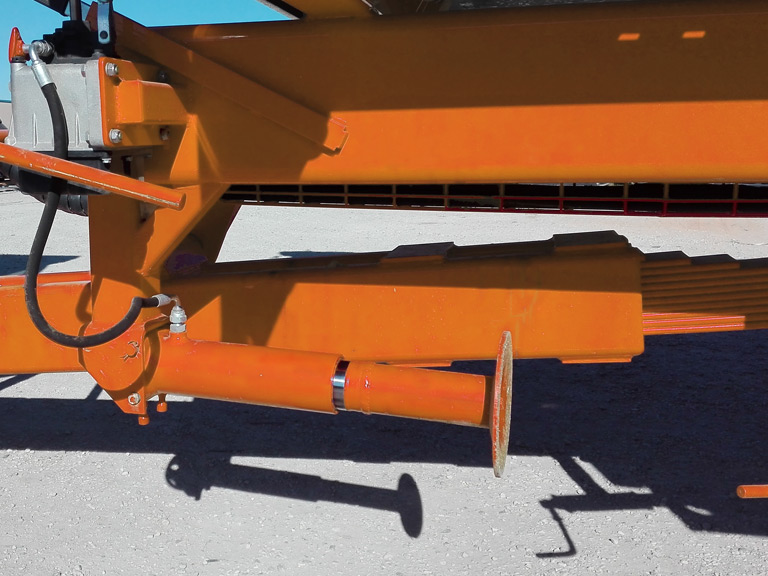

Feed belt drive is equipped with two individual tracking wheels connected to the steering (driving wheels) on both sides to prevent stopping of the feed belt drive. Hydraulic option drive is provided as an option too.

Technical information

| Hopper capacity/volume | 15-20 m3 |

|---|---|

| Road speed | 50 km/h |

| Working speed | 25 km/h |

| Full length | 7900 mm |

| Width | 2550 mm |

| Height | 2930 mm |

| Weight overall | 6260 kg |

| Hopper length | 5000 mm |

| Hopper width | 2400 mm |

| Axle | Individual steering wheels on leaves spring system |

| Tyres |

710/45-22.5 650/55-22.5 600/50-22.5 550/60-22.5 |